Recently, Megvii Robotics, with 3A intelligent solutions and business team, was invited to attend the "2023 National New Energy (lithium) Supply Chain and Logistics Technology Summit" held by Logistics Technology New Media. Megvii set up a booth to have in-depth communication with various enterprise partners in the lithium industry chain. At the summit, lithium owners shared the common pain points, current solutions and corresponding shortcomings of the industry in the field of storage and logistics in the lithium industry.

Megvii Robotics has been deeply involved in the upstream and downstream of the lithium industry for many years, which has maintained close cooperation with leading companies such as CATL, Ganfeng Lithium Group, Zichen Technology, Taifeng Pulead, Shanghai Batterotech, etc. In the following article, Megvii Robotics responded to the main questions raised by the guests on the spot, combined with the practices in the lithium industry.

The trend of lithium industry

The whole industry after nearly 2-3 years of expansion, the investment enthusiasm gradually returns to rational. With the new production capacity of the lithium industry chain, the industry chain especially the upstream material supply shortage has been eased. As the price of lithium carbonate has gradually fallen from a high of 600,000 / ton to 400,000 / ton a few days ago. It is worth optimistic that the market outlook and profitability of the entire lithium battery industry is still better than most manufacturing industries. With the outbreak of the energy storage market, lithium batteries will gain a new growth stage.

The challenges of lithium battery logistics

1. The challenge of product-demand forecast

Compared with the automotive industry, which is a very mature industry demand forecast, the lithium battery industry demand forecast is difficult to achieve precision. There are many external demand factors, such as the emergence of new forces and the new energy vehicle market itself, as well as the volatility of upstream raw material prices.

How can lithium battery companies achieve relatively accurate inventory forecasting, and achieve the best supply chain control costs (shortage costs, capital costs, price fluctuation risks, etc.)? How to avoid excessive or scarce stockpiling that resulting inventory stagnation? Including how to coordinate the delivery time of container trucks and shipping to achieve rapid delivery?

2. The challenge of safety

Lithium batteries are flammable and explosive, therefore safety and explosion-proof issues have become the top priority. How to ensure immediate detection and alarm, as well as the most essential, how to timely extinguish the fire and do safe rescue?

3. The challenge of devices lifecycle application

Lithium battery industry is rapidly updated, from lithium iron phosphate to ternary high nickel to today's sodium ion, solid-state batteries, from blade battery to Kirin battery to 4680 cylindrical batteries. How to ensure the applicability of the whole life cycle of hardware and software equipment? From a certain stage, how to ensure the compatibility of new design solutions and the original equipment and package, will be directly related to the economy and competitiveness of the program itself. The future of the lithium industry warehousing and logistics market will be a large part in the renewal and transformation scenario.

4. The challenge of warehousing efficiency

Improving efficiency of 40% in Lithium battery industry is still in the design stage, which will determine the corresponding efficiency and operation and maintenance costs, including but not limited to hardware, carriers, etc. Are supporting enterprises forward-looking and comprehensive consideration?

5. The challenge of flexibility in automatic storage solution

The common AS/RS (automatic storage) program in Lithium battery industry is stacker crane and roller conveyor. For pallet shuttle and other flexible programs still exist efficiency (including but not limited to turning performance) and stability concerns. But for raw materials warehouse, line side warehouse and other scenarios, the whole vehicle enterprises and lithium companies are willing to open up to emerging innovative manufacturers.

6. The top challenge of saving cost

The automotive and lithium battery industries are highly automated industries with strict requirements for product quality and consistency, which objectively require machine to human replacement to reduce human errors. On the other hand, Chinese social structure determines that the recruitment, training and retention of blue-collar workers will become increasingly difficult. Thus, the unmanned and less humanized warehousing solutions will become an immediate need.

Megvii stands for “lithium” dream

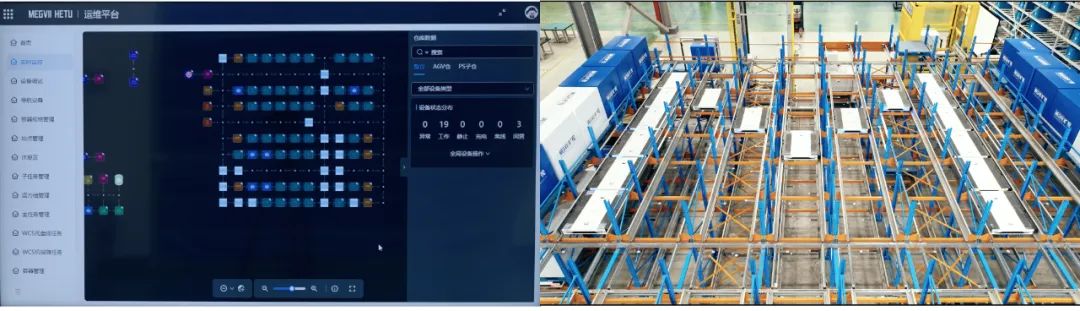

Megvii currently has independent core products: 3D pallet shuttle, autonomous mobile robot AMR, and HETU, which constitute the flexible solution: PS+AMR+Hetu.

After careful R&D in the industry, Megvii has been applied and recognized by leading customers in the lithium industry, such as CATL, Ganfeng Lithium Group, Zichen Technology, Batterotech. Megvii 3D pallet shuttle solution is distinguished by four advantages: efficient collaboration of software, stable maintenance of hardware, reliable delivery on the ground, and flexible intelligence of solution. In addition, for lithium material industry, Megvii has developed special dustproof models and supporting sweeping vehicles for lithium material to solve the problems of index identification and graphite easy conductivity in heavy dust environment.

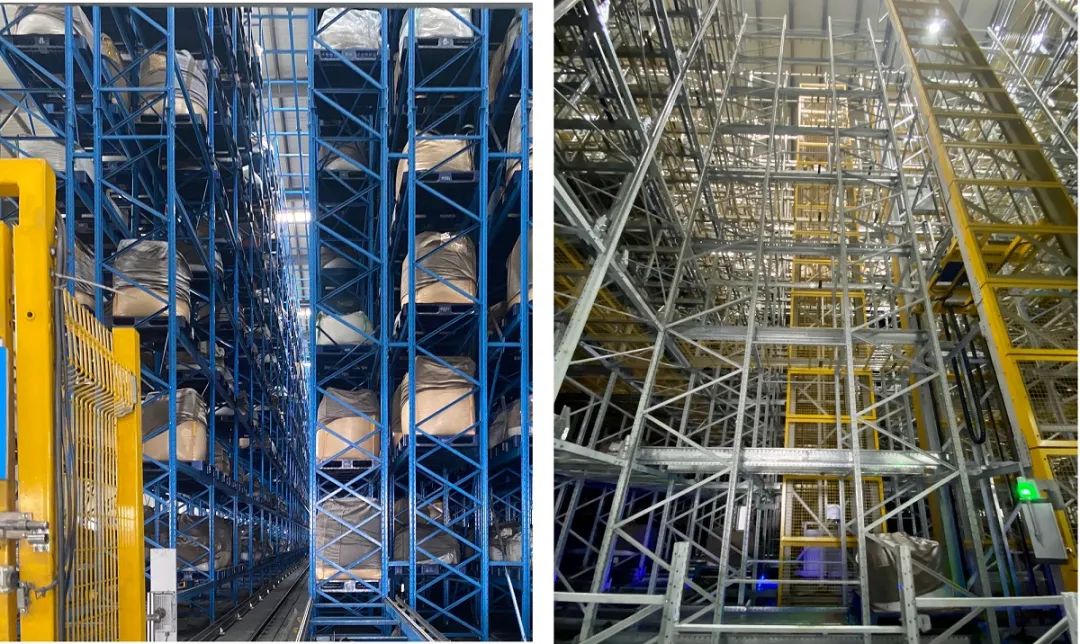

Since its launch, the Megvii 3D pallet shuttle has been delivered to more than 30 projects with a total of about 500 units of equipment, distributed in 8 major industries such as new energy, medicine, food cold chain, footwear, petrochemical, semiconductor, 3PL, machinery, electronics and electrical appliances. The largest single project (distribution center) has applied more than 80 units, and the Hetu system has dispatched a total of about 700 units of multi-type equipment (including pallet system equipment, bin system equipment, cargo to man system, conveyor sorter, flexible handling equipment, and robotic arm), which are now stably online, with a peak daily processing order of 250,000 pieces. The system has also been developed and landed in the head customers of cold storage, medicine and other severe industries, showing the cluster scheduling, high efficiency and stability and real delivery strength of Megvii 3D pallet shuttle system.

Megvii Hetu × Megvii 3D pallet shuttle

Megvii 3D pallet shuttle solution

1. Fully flexiblility solution

dense storage + fully flexible handling + Hetu scheduling. The flexible solution can increase or decrease and change equipment with production; Hetu system is strongly compatible with various hardware and software equipment; Hardware equipment (3D pallet shuttle) has excellent turning performance and stability, high space utilization (cargo space density is at least 25% higher than stacker cranes, fully flexible handling solution does not occupy the factory moving line); Low operation and maintenance costs (including but not limited to energy consumption and carrier costs), and excellent adaptability for material and lineside bins.

Left: stacker crane storage Right: 3D pallet shuttle storage

2. The safety problem

Megvii robot is equipped with comprehensive smoke, infrared and temperature sensors, which can timely to screen fire and alarm, implement fire extinguishing and safe transfer. Equipped with a special charging device for the lithium industry, which adopts fire-resistant material external cover to avoid fire hazards that may be caused by naked charging.

3. Digital supply chain platform

Hetu system has strong algorithmic computing power and excellent tandem scheduling capability for upstream and downstream systems, which can carry out strategy self-optimization based on the operation practice of warehouse operations, as well as demand prediction and intelligent replenishment prompt based on customer needs. The underlying AI algorithm of Hetu supports Megvii to become a big data center, which supports customers to carry out accurate order prediction in cooperation with upstream and downstream and improve the comprehensive response efficiency of supply chain. Of course, this requires the cooperation of friends in the industry chain ecosystem, such as raw material enterprises, lithium battery enterprises, vehicle enterprises, warehouse management software enterprises, logistics and transportation enterprises to collaborate to open and jointly manage data interfaces, and do the integration and enhancement of the digital supply chain. Big dream, smart supply chain.

The lithium industry case study

Liyang project of Zichen Technology

The Liyang warehouse with 3D pallet shuttle + AMR