News .

Logistics Salon Interview

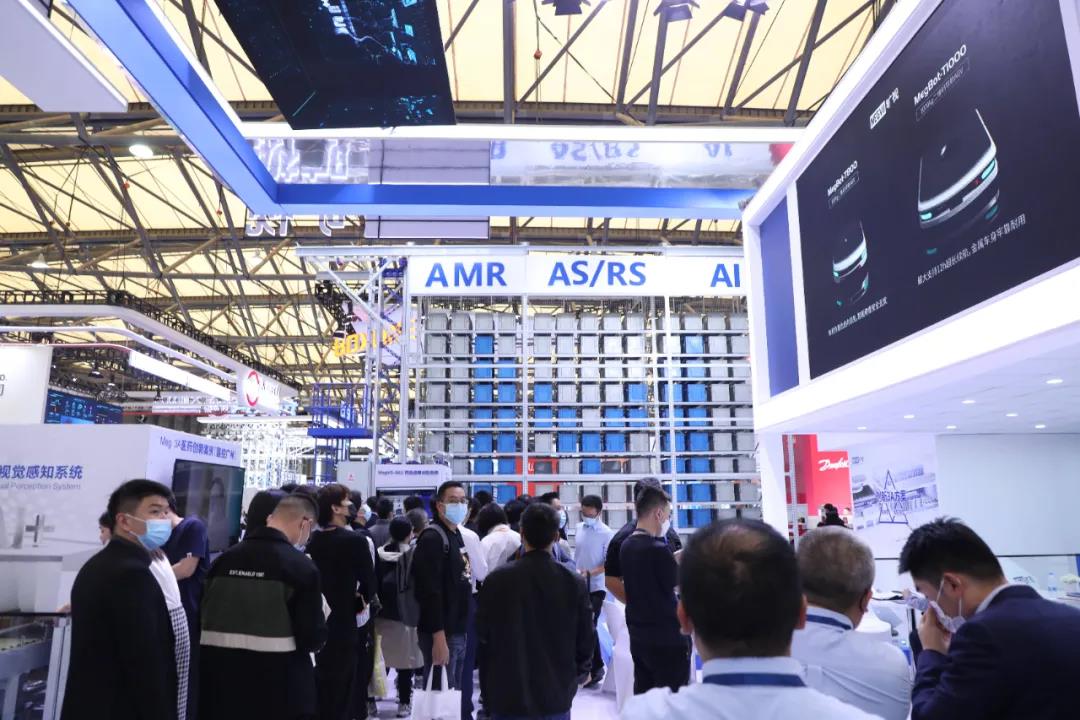

At the 2021 CeMAT ASIA, which just ended last month, the exhibitors showed great interest in the 3A smart logistics solution (AS/RS+AMR+AI) released by Megvii, and raised some specific questions, then We use the following keywords to let everyone understand Megvii's 3A smart logistics solution and the core value of Megvii's AI-enabled logistics business.

Keywords: AI+ Solution, Combining Rigidity and Flexibility

Megvii 3A smart logistics solution includes AS/RS (three-dimensional storage, including stacker, four-way vehicle storage, conveyor line) + AMR (flexible handling and picking, including P2P, G2P, G2R) + AI (machine vision, Visual perception and algorithm optimization enable software and hardware products) three major modules. This solution conducts overall scheduling through the intelligent logistics software platform Megvii Hetu, and integrates the traditional AS/RS automated logistics system with the innovative AMR flexible logistics system. And algorithms empower warehousing and logistics, combine rigidity and flexibility, and effectively help customers reduce costs, increase efficiency, and simplify management.

The 3A solution includes a series of modular products and subsystem solutions. Megvii configures them flexibly according to customer pain points and different scenarios, which can not only meet customers' needs for bulk storage and fast entry and exit, but also meet customers' flexibility and scalability. At the same time, Megvii empowers each link through AI technology to provide customers with an optimized overall solution.

Keywords: AI+ Product, Software and Hardware Integration

AI drives hardware, Megvii solidifies AI capabilities and software capabilities into hardware products, collaboratively defines product value, and builds a self-developed AIoT software and hardware integrated product system redefined by AI consisting of robots and automation equipment. important role in logistics solutions.

In the AS/RS solution, Megvii has created a series of core logistics equipment products including artificial intelligence stackers and artificial intelligence Miniloads. Whether it is box storage or pallet storage, it can achieve intensive storage and fast storage. Pick and Ship. The artificial intelligence Miniload exhibited on the CeMAT site: the running speed can reach 360 m/min, the speed is higher than that of most products on the market, and it has functions such as track foreign object identification and cargo inventory, which improves the safety and efficiency of operation.

Figure: AI Miniload at CeMAT site

In terms of AMR autonomous mobile robots, with advanced intelligent algorithms, Megvii has independently developed a variety of AMRs, including QR code navigation latent AMR, laser and visual SLAM navigation AMR, and laser SLAM navigation forklift AMR. Each AMR has the characteristics of intelligent perception, intelligent map update, relocation, high-precision point-to-point, three-dimensional obstacle avoidance, and high reliability. It is worth mentioning that Megvii's SLAM technology is in the first echelon of the industry. By intelligently filtering dynamic objects, Megvii SLAM technology achieves dynamic environmental adaptability that traditional laser SLAM cannot achieve. Even if the scene is 50% occluded, it can be done without getting lost. The SLAM technical team of Megvii Research Institute has won the double champion of CVPR 2020 SLAM Challenge, the world's top conference in the field of computer vision, and the champion of IROS 2021 The HILTI SLAM Challenge.

Picture: Megvii AMR at the CeMAT site

As the core cornerstone of the entire 3A program, the Megvii AI algorithm runs throughout, realizing the deep coupling and efficient collaboration between general algorithms and industry algorithms. First of all, the "Megvii Hetu" intelligent logistics software platform has completed the 2.0 upgrade, and has been applied in some large and complex projects to achieve unified scheduling of thousands of different types of logistics equipment, and obtain Second, AI endows AMR robots with better environmental perception and obstacle detection capabilities, and with the empowerment of powerful operational research optimization algorithms, more efficient task matching and path planning can be achieved. AI is also deeply integrated with traditional industrial robots (such as picking robots) to provide visual picking capabilities with higher accuracy and recognition rate, enabling seamless switching and orderly placement of SKUs during picking operations.

In addition, Megvii is well aware of the pain points in the pharmaceutical industry, and the most painful thing is information management: the production date, shelf life, and production batch number identification of drugs need to be accurately recorded by the system. Based on algorithms and smart cameras, Megvii has developed a document information visual recognition system and a carton information visual recognition system through deep learning visual algorithms, which can easily solve the problems of strong randomness and complex symbol detection, classification and positioning, and greatly improve the digitalization of drug management. The precision and efficiency can effectively alleviate the problem of increasing labor costs.

Figure: Megvii AI Visual Perception System at CeMAT site

Keywords: AI+ Scene, Value Landing

Based on leading solutions and products, Megvii focuses on industry needs, deeply integrates AI and IoT technologies, and empowers three major scenarios: smart parks, smart warehouses, and smart micro-warehouses (micro-fulfillment centers), providing customers with services including planning, The one-stop service of simulation, implementation and operation has achieved stable value implementation and helped industry customers to reduce costs and increase efficiency.

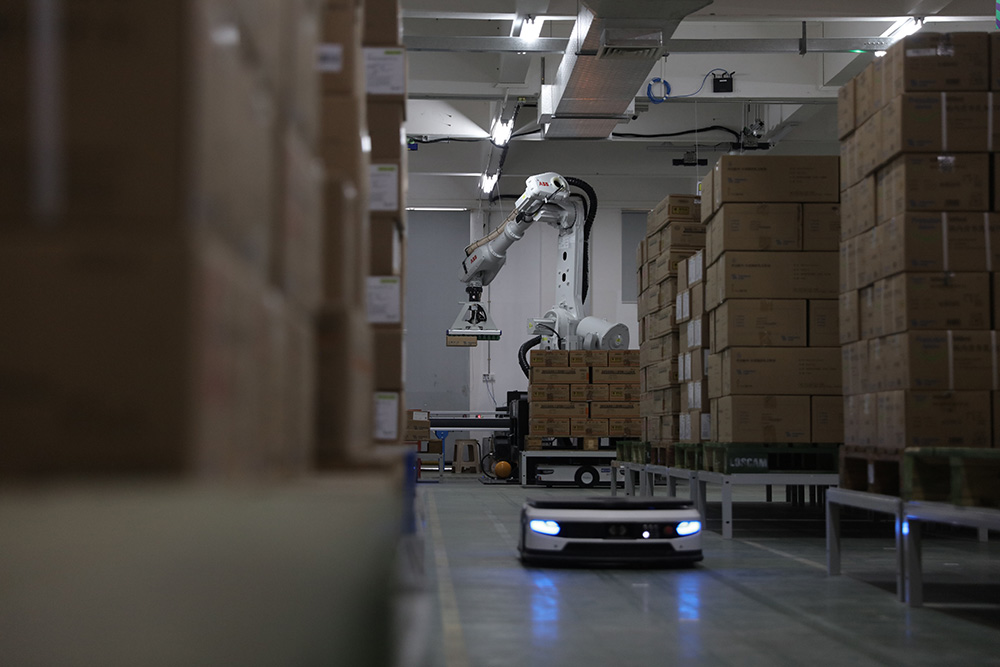

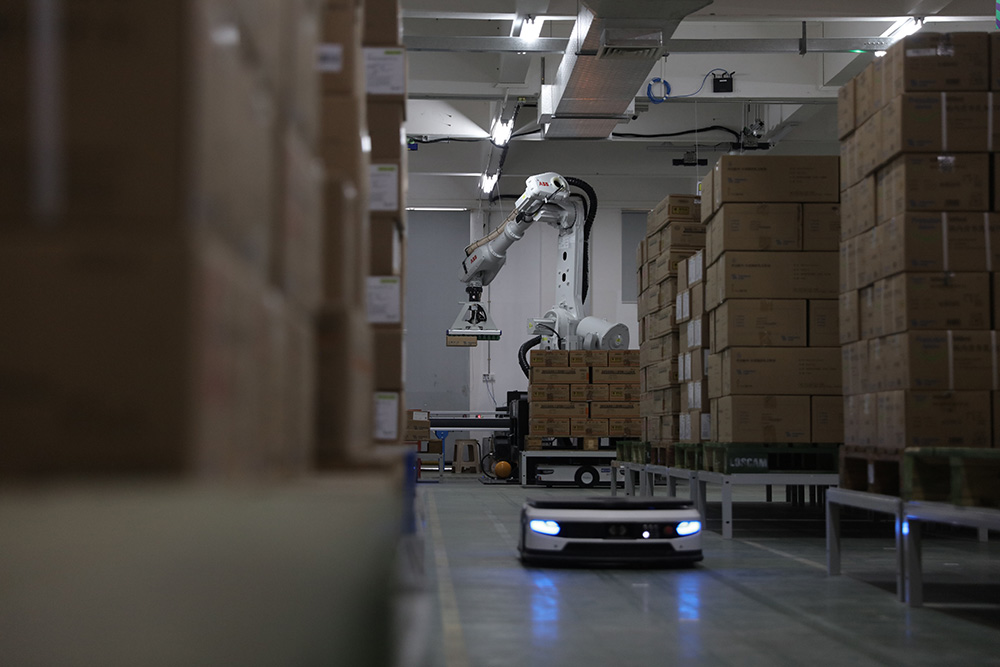

We found that in the field of pharmaceutical distribution, Megvii has in-depth cooperation with Sinopharm Holding Guangzhou Co., Ltd. ("Sinopharm Guangzhou"). In 2020, Sinopharm Guangzhou began to introduce the AMR robot and AI technology developed by Megvii. With the help of the ingenious design of dual warehouses and China Unicom and the leading 3A smart logistics solutions, the automated logistics center, which has been in production for 12 years, will be seamless and non-stop. Intelligent transformation. After completing the upgrade together with Megvii, the storage density of Sinopharm Guangzhou Logistics Center has increased by 15%, the overall efficiency has increased by 25%, and the operation completion time has been advanced by 2 hours; without the need to increase the warehouse operation area, it can meet the continuous growth in the next few years. volume of business. From an average daily load of 30,000 kilograms, to the automatic depalletizing and palletizing of the robotic arm, the warehouse staff realizes unmanned operation, and the efficiency is increased by 106%; marathon. In general, Megvii and Sinopharm Guangzhou have explored an upgrade road without construction and reconstruction, which will save tens of millions of yuan for Sinopharm Guangzhou in the next five years.

On the whole, the Megvii 3A smart logistics solution has the advantages of innovation, flexibility, efficiency, and scalability, helping enterprises to upgrade their digital intelligence, so as to improve the cost-effectiveness and flexibility of the overall supply chain, and effectively help customers shorten construction periods and reduce costs. , increase production capacity and create value.

Keywords: AI + Logistics, Industrial Upgrading

In the past 100 years, every transformation of the logistics industry has been related to infrastructure and technology, and the agile supply chain system built by core technologies such as artificial intelligence and the Internet of Things will profoundly affect and change the logistics industry in the next five years.

Megvii believes that with the increasingly complex business needs, flexible and discrete logistics subsystems in logistics scenarios continue to emerge, and various types of robots and automation equipment are widely used. A truly intelligent logistics warehousing system is not a simple combination of equipment, but a system based on The full application of thinking to the function of the device. This is a complex process of global optimization, which requires a forward-looking perspective to understand customer needs, and more importantly, requires innovative technologies to form a new generation of solutions.

With advanced AI technology and an experienced team in the industry, Megvii firmly believes that it can help upgrade the logistics supply chain industry and move closer to a digital, intelligent and flexible future.

Source: Rogo Net