![]()

An e-commerce company is the largest CP warehousing operator in Cainiao. It has established overseas operation centers in 17 locations around the world. Its warehouse and distribution network covers more than 350 cities across the country, with 388 global supply chain networks and a warehouse area under management of more than 1.7 million square meters; daily peak The order processing capacity reaches 25 million pieces. Enterprises hope to upgrade their warehouses in terms of a large number of inventory units and a large number of complex customer order processing, operational efficiency and user experience.

![]()

As a large-scale warehousing project in the e-commerce logistics industry, the warehouse has a large number of SKUs, massive orders, and high order volatility. It has pain points such as complex demands, overlapping operation processes, and high labor intensity, and it needs to consume a lot of labor costs. At the same time, enterprises have high requirements for timeliness and operational efficiency, and the difficulty of logistics operations is cumbersome and complicated. In this regard, the client put forward the requirements for the project to complete high-efficiency, zero-error, and automated operation transformation with the least manual intervention.

![]()

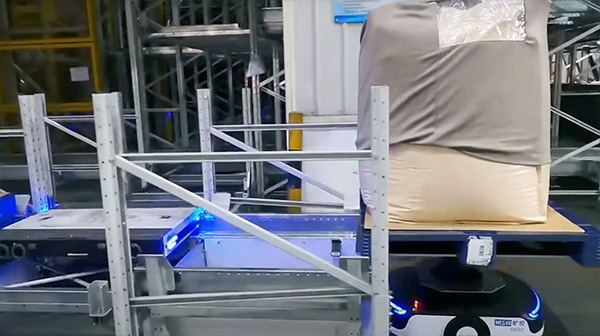

According to the project requirements and the characteristics of e-commerce logistics, Megvii customizes the "multi-mode integration solution of goods-to-person + order-to-person + point-to-point handling" for e-commerce picking operations. The solution is based on the new generation AI productivity platform Brain++ to optimize the operation process. At the same time, Hetu dispatches robots to realize the mixed application of "order-to-person", "goods-to-person" and other handling and picking modes, giving full play to the robot's "running errands" role and manual Mobility and flexibility.

![]()

The process of order-to-person solution is divided into dispatching orders (the system issues wave order tasks), order vehicle searching (robots carry vehicles to pick shelves to picking stations in various picking lanes), and regional picking (regional pickers carry out "fruit picking"). ” picking), complete picking (the robot runs through the picking stations involved in the task in sequence according to the scheduling instructions, and completes the picking “to pick”), sowing (the robot carries the rack to the seeding wall, and the seeding is done manually) , review, packaging, weighing, collection and delivery of 10 links.

The "goods-to-person" solution process is divided into the following links: dispatching orders, robots moving designated shelves to the picking work area, completing picking, reviewing, packing, weighing, collecting and shipping.

The plan deploys a warehouse area of 50,000+ square meters. Hetu cooperates with more than 500 robots to achieve zero mistakes in mass sorting work. The labor efficiency is increased by 40%, and the manpower is saved by 57%. The efficiency is increased from 140 pieces/person/hour to 220 pieces/hour. Person/hour, create 2 shifts and an average daily scale of 80,000 orders, which can effectively save the overall operating cost by 20%~30%, and reduce the damage rate of goods by 30%~40%.

This solution is widely used in e-commerce, retail, warehousing and picking in the 3PL industry and other business types. It is suitable for picking scenarios where the warehouse has a large picking area, and there are many orders and single pieces.

![]()

The project combines "order-to-person", "goods-to-person", "point-to-point handling" and other modes in the e-commerce picking operation scenario. It is an effective implementation of the integration of artificial intelligence technology and the Internet of Things. It can work efficiently and collaboratively with more than 500 robot warehouses at the same time. During the "Double Eleven" shopping carnival in 2018, the solution enabled the warehouse to operate efficiently 24/7 throughout the week, efficiently picking and storing more than 1 million items, and dismantling more than 80,000 boxes on the same day, refreshing the single warehouse The industry records of robot cluster operations have important reference value for practitioners in other industries.