![]()

A well-known enterprise in Tangshan is a pillar enterprise of local taxation. Its business scope includes the production of sanitary ceramic products and self-operated import and export of sanitary facilities. With advanced and mature manufacturing technology and efficient production capacity, with an annual production capacity of 9 million pieces, it provides services to more than 40 countries and regions around the world, including the United States, Canada, Australia, France, and Japan, and its export volume ranks nationally for three consecutive years. come first.

![]()

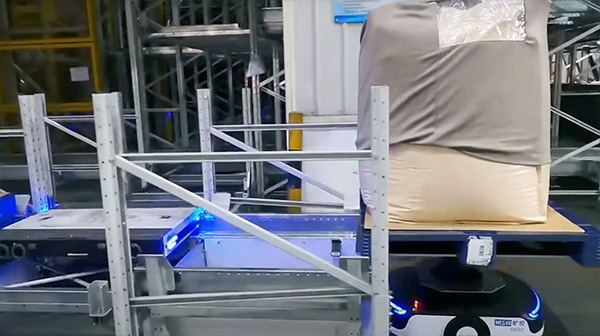

Labor-intensive industries such as sanitary ware are gradually moving towards production automation. They hope to link with production lines to greatly increase inventory and improve the efficiency of goods in and out of the warehouse, so that enterprises can carry higher production tasks and meet the needs of social use. In this regard, Megvii has customized an automated three-dimensional warehouse system for a well-known enterprise in Tangshan to help realize the automation of the whole process of products from production to delivery, and build an intelligent production base in an all-round way.

![]()

According to the needs of a well-known enterprise warehousing logistics distribution center in Tangshan and the characteristics of the sanitary ware industry, Megvii has created an automated three-dimensional warehouse system for use in new customer projects. Through the all-round scheduling of equipment by HETU, the plan realizes the rapid and orderly entry and exit of finished products, and further improves the management level of customer enterprises.

![]()

Through the integrated logistics system HETU, and the cooperation of stackers, shelves, pallet conveyors and other equipment, the solution helps customers to realize automatic entry and exit of finished products and semi-finished products. Compared with traditional warehouses, it greatly saves human resources and greatly improves operation efficiency.

![]()

The warehousing and logistics distribution center project of a well-known enterprise in Tangshan, Megvii, has helped the customer to realize the double improvement of storage capacity and operation efficiency. At the same time, this project is also a rare highly automated project in the sanitary ware industry, which has reference significance for the intelligent transformation of the whole industry.