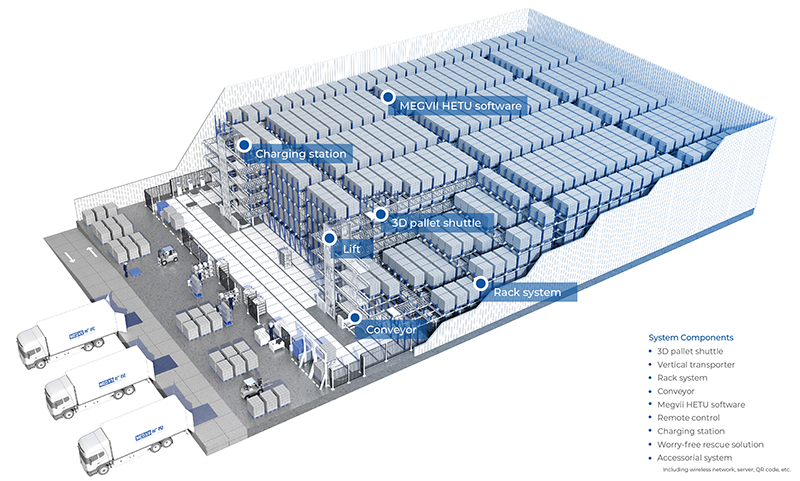

Megvii Automation & Robotics launches new generation 3D Pallet Shuttle System (3D PS) and makes a great improving for such product. The unique design and distributed control architecture, as well as the intelligent software empowered by Megvil's Al platform, make this system as representative of the new generation of pallet shuttle.

Following the product launch, several hundred units were deployed globally, with the largest project involving over 80 pallet shuttles. 3D pallet shuttle system has the potential to increase capacity, improve space utilization, reduce energy consumption and CO2 emissions and more higher productivity, whether it's in a distribution center or automated warehouse.