![]()

A Chengdu Automobile Exteriors Co., Ltd. is mainly engaged in the production of front and rear bumpers of automobiles, covering an area of 43,165 square meters and a total construction area of 20,281 square meters.

![]()

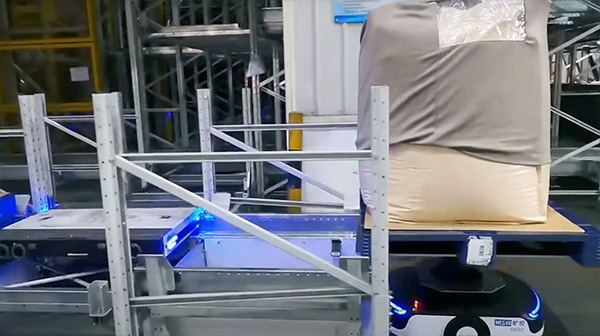

With the continuous development of the industry and the trend of automation, the requirements of auto parts production for workshops are also increasing. Megvii has customized an automation transformation and three-dimensional warehouse construction project for an automotive exterior decoration company in Chengdu. In view of the harsh workshop environment and the increasing demand for product customization, through the semi-finished automatic three-dimensional warehouse, pallet conveyor system, pallet elevator system, The steel structure platform and WMS/WCS are deployed to connect all production lines in the injection molding area, spraying area, and assembly area to realize the optimization of production quality and efficiency, as well as the production environment.

![]()

According to customer needs and industry characteristics, Megvii realizes the automatic handling of materials and the automatic supply of empty pallets by connecting various production links; realizes the material cache in the production process through the automatic three-dimensional warehouse of semi-finished products/finished products to balance the production of each production link. Efficiency; online quality inspection and sorting of materials supplied to each production line are realized through the conveyor system.

![]()

The automation transformation and three-dimensional warehouse construction scheme consists of shelves, stackers, pallet conveyor systems, pallet elevator systems, WCS and WMS. Among them, the first floor is mainly equipped with three-dimensional warehouse shelves, stackers and supporting equipment, line-side conveyors and interface operation platforms in each production workshop, and reserved manual moving lines, three-dimensional warehouse entry/exit manual operation areas, and empty pallets Artificial supply port; the second floor is erected on a steel platform, and the main conveying line between each production workshop and the three-dimensional warehouse or quality inspection area, as well as the loop line of the quality inspection area, are mainly arranged.

![]()